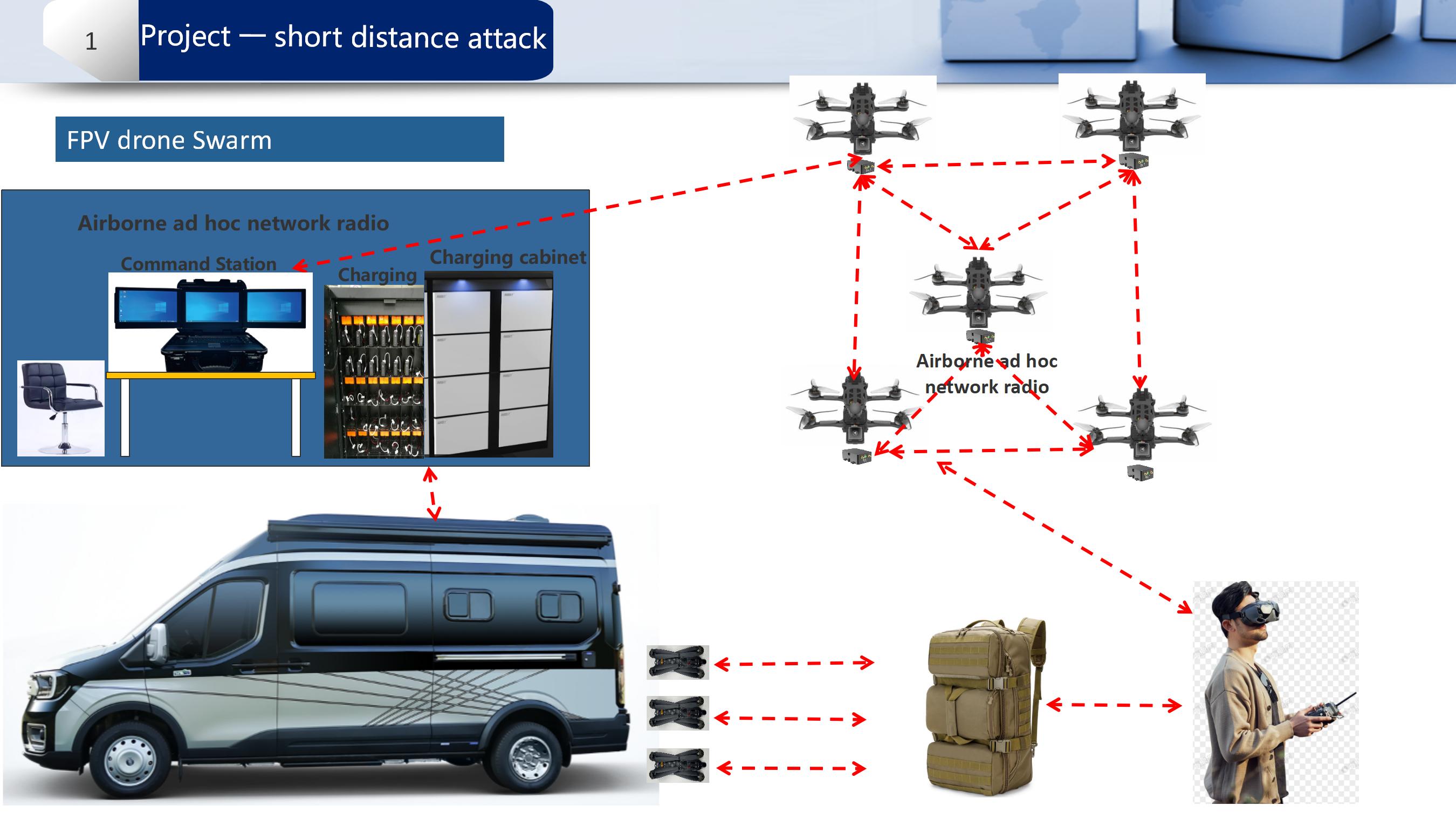

Solution

Establish an UAV factory cooperation

One、Importance of establishing a UAV plant

With the maturity of drone technology and its wide application in agriculture, firefighting, scientific exploration, emergency medical treatment, security surveillance and military reconnaissance, the technology has become an important manifestation of the country's scientific and technological and national defense strength. Under the current background of international export control, independent research and development of drones and realization of industrial upgrading are the only way to development.

Two、Our core capabilities and services

UAV technology integrates cutting-edge achievements in aerospace composites, aerodynamics, electronic communications, flight control, infrared imaging, AI and other technologies. depending on the perfect domestic supply chain system, we can provide the following support to our partners:

1.Manufacturing

- **factory planning**:Set up a complete UAV Production line, process design, technical workers training and quality control system;

- **Testing service**:UAV Assembly and debugging, performance testing, and environmental adaptability verification.

2. Product development

- Customized solution design;

- New product development and iterative upgrade support;

3. Supply chain management

- Global procurement for raw materials of aviation composites, engine systems, precision components, etc;

- Localized production support and suppliers cooperation establishment.

4.Finished UAV product assembly and pilot training

- Provide professional training to technicians based on different drone models and applications.

- Pilot training: Flight testing of prototype aircraft and debugging of flight control system parameters to know well different application modes.

Three、Our advantages

1. More than 10 years of production management experience;

2. Professional UAV factory;

3. Rich experience in technical R&D and personnel management as well as a complete training site and environment.

Four、Plant establishment Principle

1. **Investment guarantee**:Ensure that capital investment matches expected returns through detailed planning;

2. **Transparent collaboration**:The principles of open, fair and justice protect the rights / interests of both parties;

3. **Clear responsibilities**:

- We focus on technical support but do not participate in the investment party's business decision-making;

- Investment party must ensure the personal safety, information security and compliance confidentiality of the technical team;

- Both parties jointly maintain operational support for the supply chain and production sites.

Five、Cooperation Implementation Plan

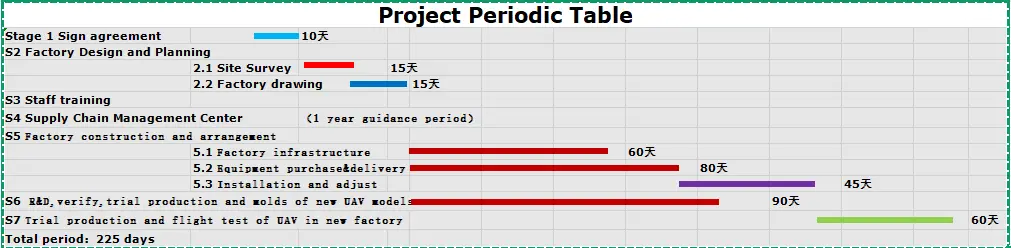

First Stage : details confirmation, agreement signing and Start-up capital (10 days)

- **main**:

1. Confirm the cooperation model, time and implementation plan;

2. Sign a legally contract.

Second Stage:Factory Design and Planning (30 days)

Requirements**

- **UAV factory construction Standard**:

- Area≥4000㎡, height≥4.5m;

-Power 500KVA, Equipped with backup power supply(Diesel generator or energy storage).

- **Flight test site**:

- Runway length 300-500 meters;

- There are no buildings blocking the view within a 2km radius, the airflow is stable and the visibility is good.

**Implementation Process**

1. **Site Survey**:

- Send building electrical engineers and factory chief engineers for actual site checking (15 days);

- The investor needs to provide the site CAD drawings and a professional personnel (who must have factory construction experience and good English communication skills).

2. **Design drawing**:

- A third-party qualified design institute will issue floor plans, renderings and equipment lists (15 days);

- The drawings must include workshop partitions (warehouse, production line, laboratory, etc), water, electricity and environmental protection systems and test flight field planning.

Third Stage:Staff training

We will provide free training for the following staff to you: 1 production supervisor; 1 technical operator for precision engraving machine tools; 1 assembly tester; 1 pilot. You need to choose the right personnel qualified for relative job, and you will provide all travel expenses and salaries during the cooperation period.

Fourth Stage:Supply Chain Management Center established

**Office, equipment, accommodation;

- **Required Personnel**:

- 1-2 Aviation professional on-site staff (college degree or above, with supply chain negotiation ability);

- You will pay for your staff Salaries and daily support costs.

- **Functional scope**:

-Composite material procurement, engine system customization, mechanical parts processing cooperation and supplier relationship management.

Fifth Stage:Factory construction and equipment purchase and delivery (need time: 80 days + 45 days, total 125 days)

1. **Factory construction**:

- You are responsible for the infrastructure construction, we provide remote technical guidance;

- The construction period shall be subject to the progress of the capital party.

2. **Equipment procurement and installation**:

- The supply chain center confirms the equipment list and completes the purchase;

- We will send two technicians to provide on-site guidance on installation and adjust.

Sixth Stage:Prototype development, trial production and trial production of new UAV models (Time: 90 days)

- **UAV Sample**:1 sample of each of the 3 models + 1 set of molds + accessories (including drawings and production process documents);

Important Note: Since our UAV are clearly recognizable, in order to avoid supervision, we need make some modifications, develop and trial manufacturing them. (Any changes in appearance size and aerodynamics require redesign) This means that this model is the capital side's exclusive model.

---

Seventh Stage:New factory start to make trial production and product test flight of yourself UAV (Time: 60 days)

1 - **Trial production**:

- We provide 4 engineers (1 for production management, 2 skilled senior technicians, 1 for Debugging and assembly the UAV);

- The trial production in your new factory is mainly aimed at the production of the confirmed three UAV models and production-related technical briefings, including: production workers training, establishment of safety production system, production process design, production organization structure and production department construction; technical process briefings, quality control management and other production-related.

2-System integration and flight test verification(Time:60 days)

- **Debugging equipment**:Generators, charging equipment, ground stations, debugging system software, flight control software;

- **Trial Pilot**:1 test pilot + 2 assistants (assistants need have been trained in new factory).

Important Note: Since aviation hardware parts is special hardware, it requires CNC processing, anti-rust oxidation, sandblasting and other processes. It is cheap price but requires professional technicians and equipment. so these parts need to be sourced. We will provide CNC processing hardware at bottom price for long term support. meantime propellers also need to be purchased from China factory.

Six、Project Periodic Table